One Small Step for Mini-kind

LCD displays are driven by the properties of liquid crystal, a substance that is somewhere between a liquid and a solid. The molecules in liquid crystal can re-order themselves into a number of shapes and directions called ‘phases’ and by changing the electrical characteristics applied to the LC material, that orientation can be controlled. But liquid crystal does not produce light, so in LCD displays a backlight must be placed behind the liquid crystal, which then can be used to block or pass the light through the crystal. As each pixel in an LCD display is made up of three sub-pixels (Red, green, and blue), there is a controlling TFT (Thin-film transistor) circuit behind each sub-pixel, allowing the control of the liquid crystal to be broken down into three segments for each pixel.

Once the backlight passes through each sub-pixel, it goes to a color filter, essentially a sheet covered with red, green and blue dots made of a phosphor. By using the TFTs to open or close each sub-pixel’s liquid crystal, the color of the combined three sub-pixels can be created. For example, a pixel of this color

Sounds good, right? But there is a problem. In many LCD displays the light that is needed to be transferred through (or blocked by) the liquid crystal is produced by LEDs and in less expensive displays those LEDs are placed around the edge of a translucent sheet (diffuser) that spreads the light evenly (hopefully) across the sheet. This is where the problems start however as the characteristics of liquid crystal do not allow it to completely ‘close’, so a pixel that should be black still has some of the backlight shining through, creating at dark gray dot rather than a black one. Further, in an image where there is a close proximity of a dark section and a bright section, the backlight, which is always on, will spill from the bright pixels into the dark pixels and create what is called ‘bloom’, a halo-like corona around the bright image.

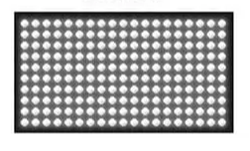

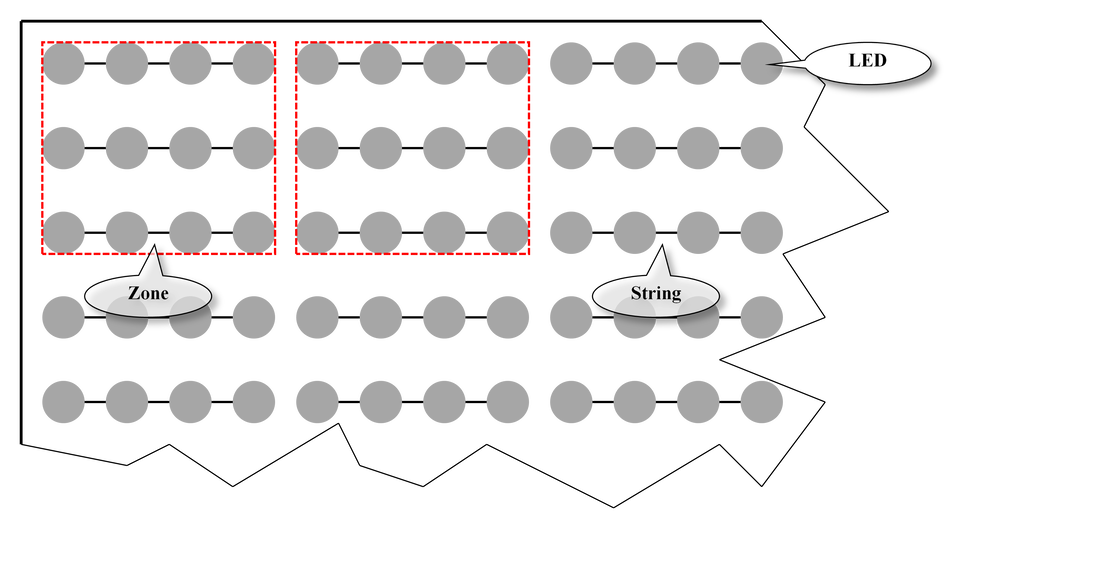

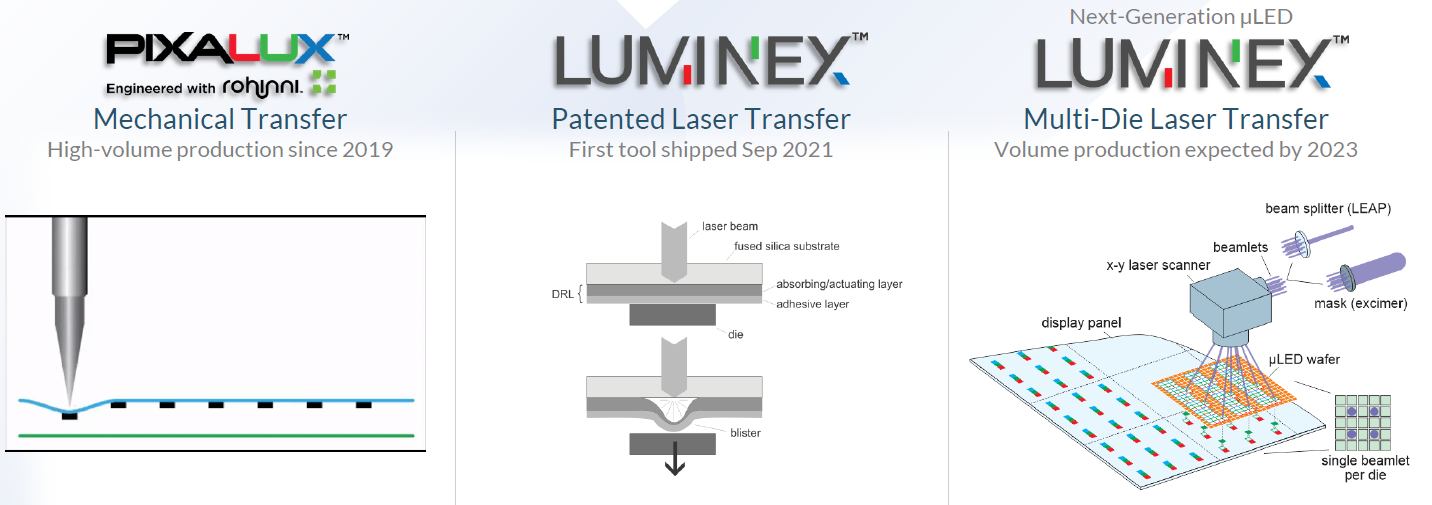

As Mini-LED backlights can contain many thousands of individually controlled small LEDs typical equipment designed to move a relatively small number of larger LEDs from a wafer to a backplane do not have the speed or accuracy to be cost effective when applied to Mini-LED production. Typical LED pick and place systems are not able to move these smaller LEDs so new equipment has been developed that can handle these components gently enough and with enough accuracy to make Mini-LEDs cost effective. One such tool that has been adopted by ‘a major consumer electronics company’ (Apple – AAPL) is produced by Kulicke & Soffa (KLIC)[1] called Pixalux.™ that the company designed jointly with Rohini (pvt). Together they developed a high speed system that ‘punches’ Mini-LEDs from a tape onto a substrate with a mechanical ‘pencil-like’ point. The speed of the system and the accuracy are better than most modified pick and place systems and the company has been the dominant player in the Mini-LED tool space.

With a top speed of ~75 LEDs/second, populating a Mini-LED backlight with 135,000 Mini-LEDs using the Pixalux tool would take about 30 minutes and the accuracy would be limited to <20um, meaning there would be limitations on LED density, but KLIC has just taken the industry a step further and shipped its next tool for Mini-LED production. The Luminex™ tool is based on a very different process for transfer, using a laser to heat a double layered tape containing Mini-LEDs. The heat of the laser creates a bubble in the tape layer on which the Mini-LEDs are attached and pops the Mini-LED off without any physical contact. This system, which was developed by K&S and a formerly private firm, Uniquarta (pvt), now owned by KLIC, can move up to 1,000 Mini-LEDs/second, at an accuracy of <10um, which would reduce the time to process the same 135,000 Mini-LED array from ~30 minutes to 2.25 minutes, increasing the throughput by over 12 times.

All said, the transfer process is only one step, albeit an important one, in the manufacturing of Mini-LED backlights. Before they are transferred, the Mini-LED dies have to be created via MOCVD, which is usually done on three separate wafer, one for each color (Blue & green use similar process materials, but red uses different materials). The die then have to be sorted (performance characteristics) and combined and usually placed on a temporary substrate before being placed on the final array substrate. These processes are typically done with other tools, however K&S has included the sorting, mixing, and temporary placement steps in the Luminex tool, which has made the new tool not only faster and more accurate, but has reduced the overall cost of ownership across the Mini-LED production line.

Given that it has taken K&S about two years to develop each Mini-LED transfer iteration, they have set a roadmap for the next generation of Mini-LED processing tools that will take the Luminex laser technology and by splitting the beam would be able to transfer at a rate of 10,000 LEDs/second at an accuracy of <1um. While we don’t expect to see that tool until 2023, it will have applications for both Mini-LEDs and Micro-LEDs, another display technology that is still in the development stage but has the potential to be a significant part of the display space over the next decade. Of course there are still other bottlenecks that will keep Mini-LED costs non-competitive for a period of time, but with each equipment iteration, the ability of Mini-LED manufacturers to bring costs in line with other display modes increases, and based on even the most conservative estimates, the Mini-LED market is expected to grow rapidly in both units and dollars over the next 4 years. Hopefully display producers will use those cost savings to bring down premiums on Mini-LED products (see our note from 9/29/21 for details) and enable more cost conscious consumers to avail themselves of the technology.

[1] Please note that we have no financial or business relationship with KLIC. We speak to the company on occasion and receive no compensation or proprietary information, as is the case with all of our sources.

07/13/21 - http://scmr-llc.com/blog/micro-led-madness

02/12/21 – http://scmr-llc.com/blog/micro-led-primer

02/08/21 – http://scmr-llc.com/blog/klic-buys-uniqarta

RSS Feed

RSS Feed