Components – More Details

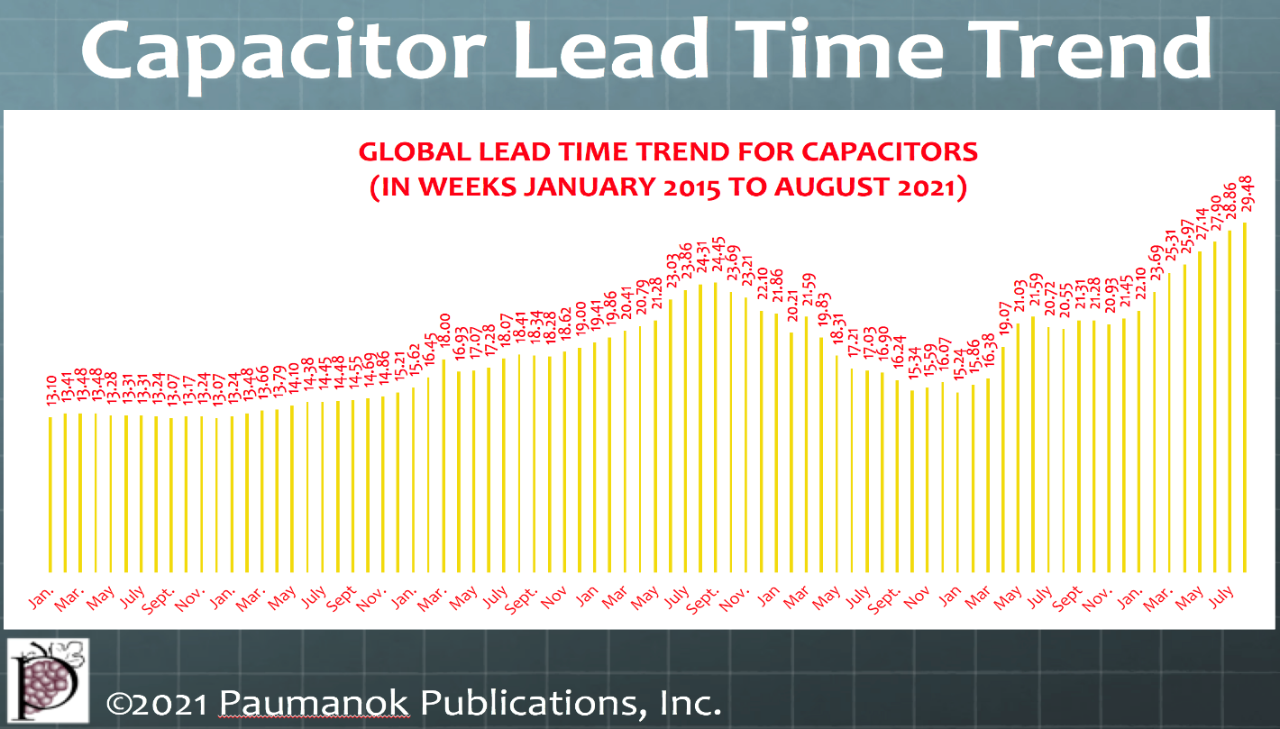

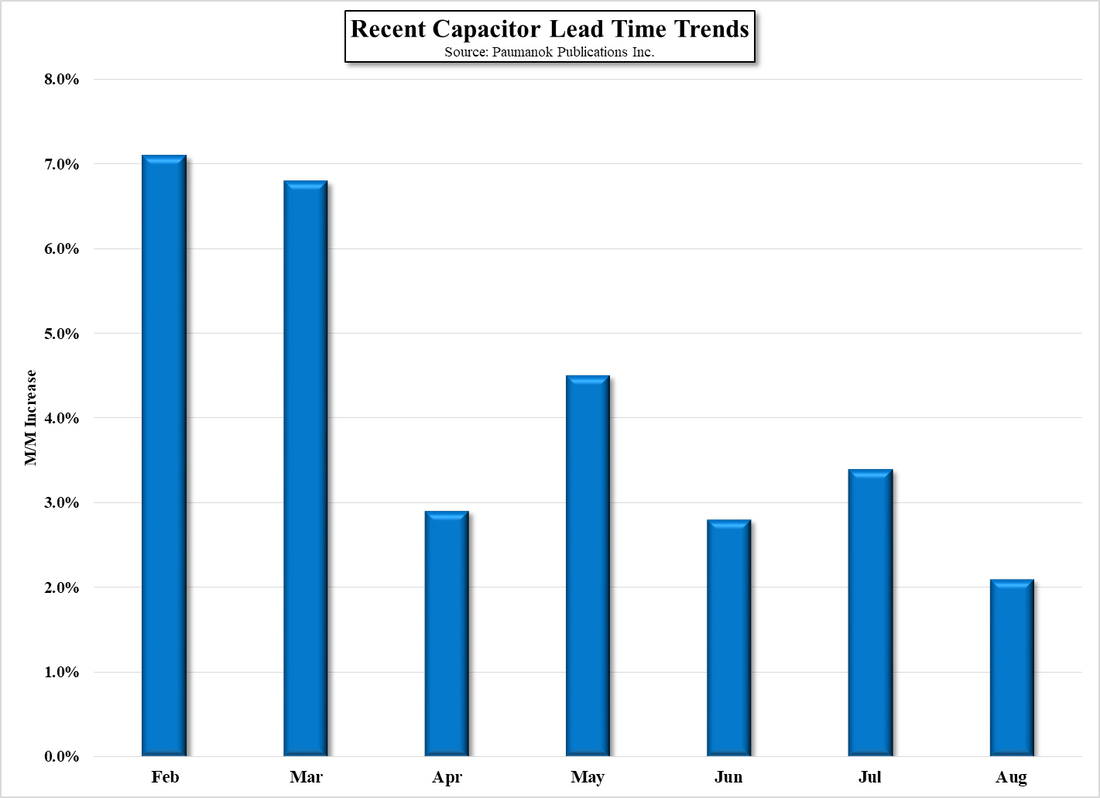

Fig. 1 shows the long-term lead time trends for capacitors on a general basis and Fig. 2 shows lead time changes for the last few months. We have focused our attention on MLCCs ((Multi-Layer Ceramic Capacitor), as they have become an even more integral part of a number of consumer electronics products (5G smartphones, electric & hybrid automotive systems, etc.), and they continue to see lead time increases and increasing demand and sales, with 3Q expectations for a 15% q/q increase in sales, but lead times for other capacitors (aluminum, tantalum, etc.) have also been increasing as supply disruptions in Malaysia and rapidly increasing raw material costs take their toll.

Tantalum concentrate alone has seen a 33.02% increase in price over the last 12 months while ruthenium, also a basic resistor material, has increased 158.6% over the same period. While some of the factors that have caused price and lead time spikes over the last year are COVID-19 related and are considered ‘transitory’ by some, the net is that we have to live with what is available and for capacitors, which have typically been easily sourced, that could mean waiting as long as 48 weeks for certain products. With well-planned ordering, lead times of 20 weeks to 24 weeks are barely tolerable, but for products where lead times are greater than 6 months, we would expect either end product delays or eventual product cancellations unless you have the buying power of Apple (AAPL) or Samsung (005930.KS).

RSS Feed

RSS Feed