LG Ink-jet Printed OLED

OLED TVs are produced differently however, with two OLED materials coated across the entire substrate. The light that is created by mixing these two OLED materials is white and then passes through a color filter, essentially a sheet of red, green, and blue phosphor dots that convert the white light to the three colors necessary to create an image, all of which are individually controlled by TFT (Thin-film transistor) circuitry.

In both cases OLED material is not only coating the substrate but also the mask and the walls of the deposition chamber, and over time the process needs to be stopped, the mask replaced, and the chamber cleaned. Not only is what is an expensive material wasted, but the downtime raises the cost of the process. In order to increase the efficiency of OLED material usage, a number of companies have come up with a process that deposits the OLED materials as ‘inks’ from what is essentially a large scale ink-jet printer that places the materials in precise locations on the substrate without a mask. In theory this process should be close to 100% efficiency as to material usage and has significant control over ink placement, but no without limitations.

As the OLED materials must be dissolved in a solution to allow them to pass through the ink-jets, the solvent and OLED material mixture must not change the characteristics of the resulting OLED ‘dot’, and the time it takes to ‘cure’ (dry) the ink is also a gating factor as to the speed of the process. Solution based OLED materials are becoming more refined and comparable to OLED deposition materials, but the ink-jet process for RGB OLED is relatively new and still being developed. JOLED (pvt), a spin-off of Japan Display (6740.JP) seems to be the leader in the printed OLED category, along with JDI itself, and while LG Display (LPL) is able to produce both RGB and WOLED (White OLED), they have opted to use JOLED’s ink-jet printed OLED display panel for their first OLED monitor.

The display itself has a number of characteristics that set it apart from more typical monitors, but the primary difference (aside from price) are the color characteristics. OLEDs displays in general are prized for their color accuracy and this monitor is both factory calibrated and allows the user to make modifications to settings and store them for later use. This is essential for those who work I the video industry, particularly colorists, who are responsible for maintaining a consistent set of characteristics throughout an film. This is an indication as to where LG expects its target market to be for this device as it does not have a number of the characteristics needed for gaming, a fast-growing sub-set of the monitor segment. It does have higher resolution (4K) than most monitors, although gaming monitors using 4K are becoming more common, but at a 60Hz refresh rate, most gamers will assume the display is not fast enough to prevent image smearing.

The LG monitor is also lacking in brightness, a bit of an issue for OLED displays generally, or at least those using a color filter, as the CF only allows the light for a single color dot to pass through, blocking the other two, which reduces the brightness of the display. That said, as the target audience, colorists and video production engineers will likely be using the display in a low light setting, it would be less of an issue in those applications. While the price is $4,000 this is not unusual for monitors that are designed for such applications as we have seen such monitors run over $10,000, we expect the use of the ink-jet process for OLED displays, even in this limited setting and application, should bring down the overall cost of IJP based display OLED displays when compared to typical deposition based OLED displays. That said this will not be a rapid change as IJP OLED is not yet a common process and tends to be used in highly specialized applications that can absorb the higher current cost of what will one day become a lower cost process.

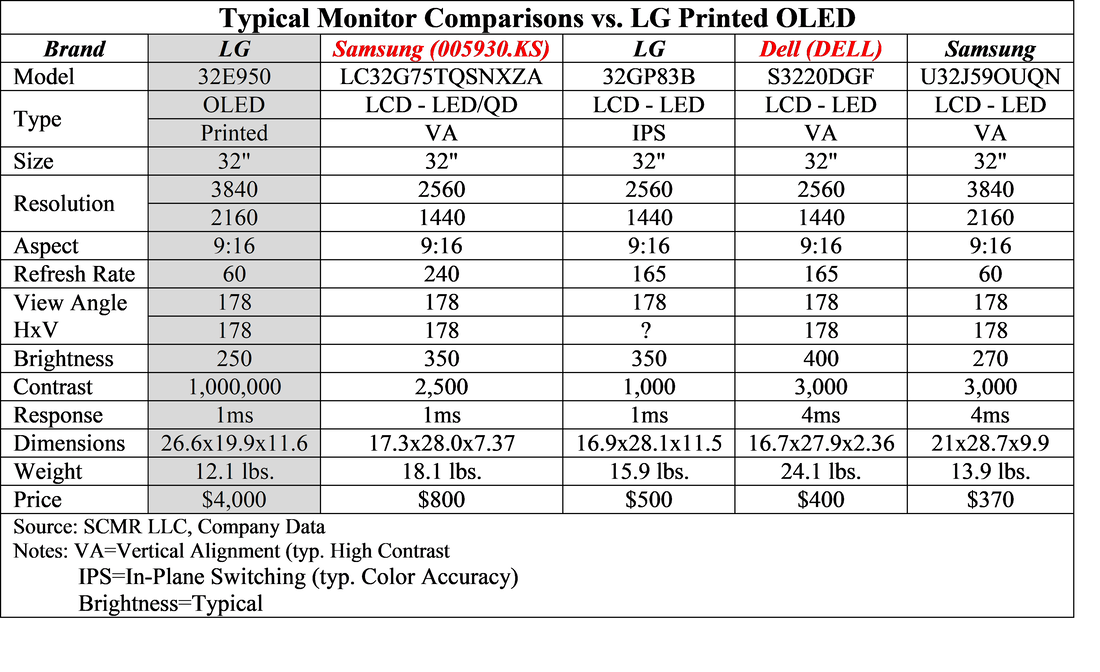

We compare a number of currently available monitors in the table below, although we note that color characteristics for many monitors are not available from manufacturers and typically are far from those of the new LG monitor:

RSS Feed

RSS Feed