Kateeva adds manufacturing space

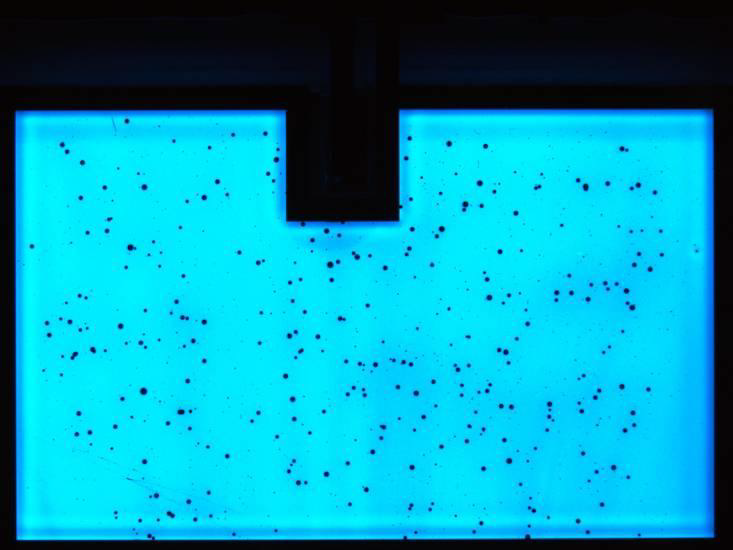

Typically, OLED encapsulation is done with thin glass and an epoxy or glass frit sealer with desiccant to absorb any water that might be present. However flexible displays represent a bigger challenge to encapsulation and a number of materials and methods have been proposed, tested and put into production to meet the goal of keeping flexible OLED devices from degrading through exposure to air and water. A number of OLED manufacturers are using ink-jet encapsulation at the back end of their OLED production lines to speed up the encapsulation process given that it can have as many as 10 successive layers of material, which take a substantial amount of process time to apply using other methods, leading to production bottlenecks. Ink-jet printing, which is done in a Nitrogen atmosphere can substantially improve OLED production TAC time.

While TFE is likely a lucrative business for Kateeva, the ultimate goal of ink-jet printing is OLED material patterning, which would allow a substantial reduction in OLED stack material usage. In a typical deposition reactor, OLED materials are evaporated and deposited on a substrate through a fine metal mask that sets the pattern for the materials. Unfortunately the materials are also deposited on the walls of the deposition chamber and on the mask itself, which substantially reduces the material usage efficiency and increases the downtime for chamber cleaning. Material usage efficiencies as low as 25% can be part of the evaporative deposition process. Ink-jet deposition applies the materials directly in a precise pattern, reducing material waste and increasing material efficiency to levels above 90%, a key cost savings for OLED producers.

There are problems however with ink-jet printing for OLED stack materials. The solvents needed to allow the materials to pass through high speed ink-jet heads can change the characteristics of the materials themselves, and issues like solvent drying time or bleed between sub-pixels have kept ink-jet stack material processes in the development stage for years. While Kateeva is likely adding capacity for the manufacturing of their encapsulation tools, the eventual adoption of ink-jet printing for deposition would be a milestone in the development of OLED manufacturing.

RSS Feed

RSS Feed