Touch on the iPhone 8

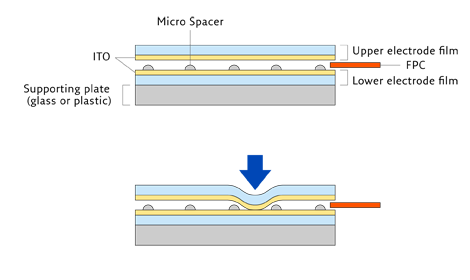

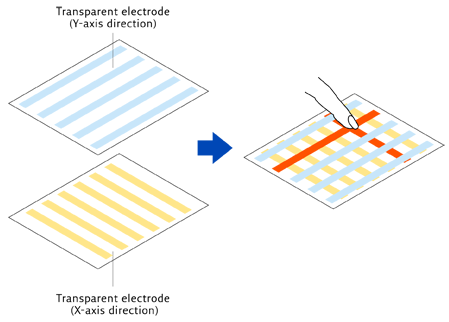

While specifics as to the type of sensors and modules was not given Nissha supplies both capacitive and resistive sensors and force sensors that detect touch pressure. Resistive sensors are relatively simple structures (see Fig.1) and capacitive sensors are slightly more complex (see Fig.2) but thin-film comparisons against glass based sensors and modules have somewhat more viable metrics for use in mobile devices, with a thickness 61% of glass, and weight of 34% of glass[1], but the general thinking here is that the touch will be an ‘add-on’ module, not the far more complex ‘in-cell’ touch that is built into the OLED display module itself. While we would expect Samsung Display (pvt), the supplier of the OLED display module, to want to capture the higher value ‘in-cell’ process, rather than have it added by a 3rd party supplier, in-cell touch technology is still relatively new to high volume manufacturing, and as such adds to the potential issues that might occur during the OLED display production. Apple is already putting itself at risk with a new technology and a new supplier, so it makes sense that they would opt for the less risky technology.

Almost as important however, is if the use of thin-film sensors is correct, it could lead one to think that the necessity for such materials would indicate that the device will not be shaped in a typical smartphone shape, with the film indicating either a rounded or flexible configuration. While it would be encouraging to imagine such a breakthrough device, it ain’t necessarily so. The film sensor modules could be used toward a conformed edge, as is the case in the Samsung Galaxy line, which would make the application of the touch module far simpler than depositing sensors on a conformed surface, so while we are encouraged by the use of TFS, we don’t assume it means something other than a potentially conformed device.

[1] Metrics supplied by Nissha

RSS Feed

RSS Feed