Samsung QD/OLED Project Update

This system differs in two ways from the approach that LG Display, the leading OLED TV panel supplier, uses for their TVs, which use two OLED layers (green/yellow and blue) that when combined generate white light. That white light then passes to a color filter that uses red, green, and blue phosphors to filter out two of the three primary colors in white light to form red, green, and blue sub-pixels. The important distinction here is that the ‘new’ QD/OLED process uses only one OLED color (blue), while the LGD process uses two and that the phosphors in the LGD color filter are ‘subtractive’, in that they remove two of the three color components and let only one through. Logic holds that when you remove components of white light you wind up with a ‘less bright’ light, which has been a criticism of OLED TVs since their inception. The ‘newer’ process uses quantum dots in the color filter, which are not subtractive but are able to shift the frequency of the light (meaning color), maintaining much of its brightness. This should allow for an overall brighter display.

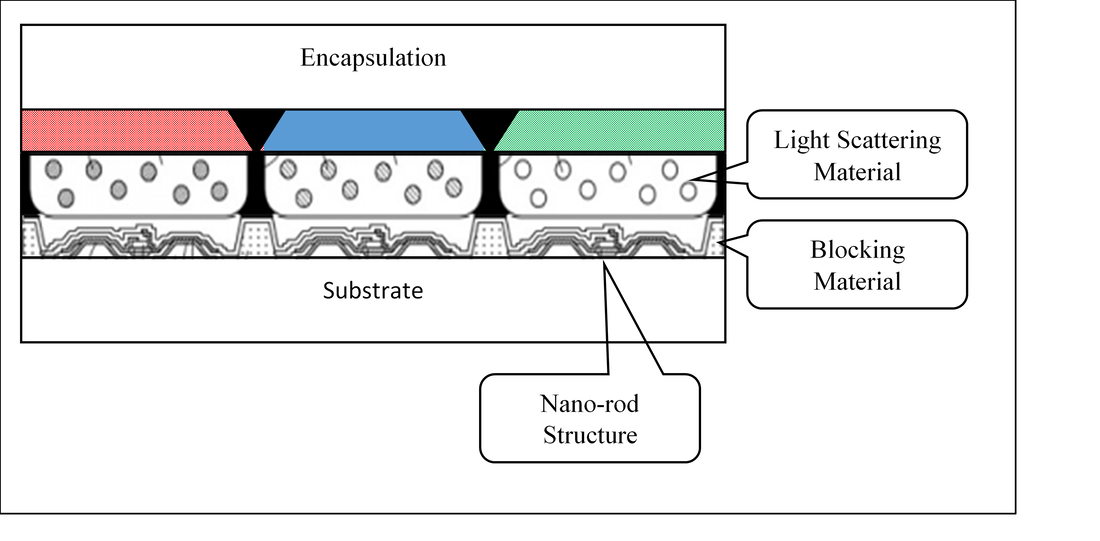

But SDC did not stop there and continued to look for other alternatives, particularly as blue OLED materials are not phosphorescent and inherently generate considerably less light than those that are phosphorescent (red and green). SDC came up with the idea of using what are known as nano-rods that are essentially very small LED ‘tubes’ that emit blue light. By substituting these nano-rods for the blue OLED material they were able to overcome the lower light output issue that was present in the alternative technology.

There is a problem however in that such nano-structures must be grown in place, must be vertically oriented, and must have an equal number in each sub-pixel. If a nano-rod is not vertical it will short other rods and the sub-pixel will fail. If the number of nano-rods in a pixel is greater or less than required, that sub-pixel will be brighter or darker than the rest, causing non-uniformity, a definite no-no in the display space. In order to compensate for these issues SDC has had to added ‘electrodes’ that ‘sense’ whether a nano-rod is ‘aligned’ and can also be used to adjust the brightness of the sub-pixel if it has too many or too few nano-rods, but all of these checks and balances add up to complexity, which adds up to cost.

That said, the goal at SDC is to be able to produce a large display that has better overall image quality than current OLED TVs, and according to some, nano-rod based displays fit that bill, however when it comes to displays, there has to be a visible path to large scale production that is cost effective, and while few new display technologies have such a clear view when in the early stages of mass production, there has to be a realistic vision of how long it will take to become viable and profitable. OLED TV panel production, at current volume levels, is just becoming profitable for LG Display, after almost nine years in production (albeit pilot line production in the early years), so the complexity of SDC’s nano-rod technology must be evaluated in the same way.

Given that the company has committed significant resources to its development and has allocated dedicated capacity for its production, SDC is certainly willing to give it a chance, and if successful will build out that capacity, but despite those who support the technology, there is considerable distance between generating the technology on a limited basis and producing a few million or so panels per year, and we likely will not see anything on a commercial level until 2022 to be able to judge both quality and generate a cost curve, although the saying “No guts, no glory” is certainly a valid one in this case.

RSS Feed

RSS Feed