Shortages – More

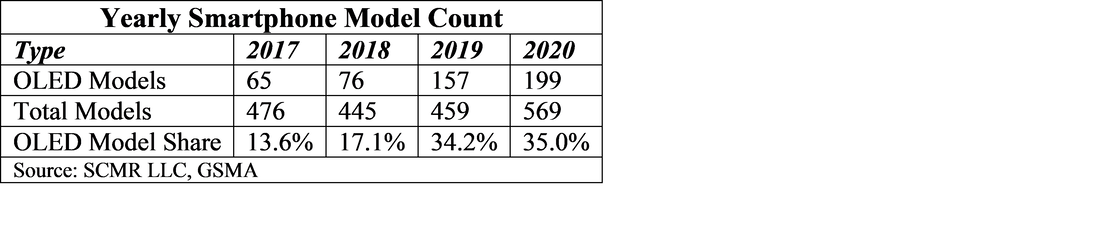

One of the largest DDIC producers is Magnachip (MX), a South Korean company listed on the NYSE. To be clear, we are not promoting Magnachip[1], but because of where they sit in the CE supply chain, their results offer some insights into the current CE shortages. Magnachip is the leader in OLED display drivers with a share close to 35%, and while overall smartphone shipments declined ~7% last year, OLED smartphone shipments and the number of new models using OLED increased as adoption of OLED displays continues in the smartphone market.

[1] We have no position in Magnachip, or any other public or private equities. We receive no compensation from any companies for promoting their products, the companies themselves, or their particular industry.

First, Magnachip, which is a fabless producer for its OLED drivers, indicated that it expected to be unable to supply ~$10m of customer demand due to supply constraints at their outside foundry (12” 28nm). They expect some of that excess demand (likely less than 50%) will carry over into 2Q, but given the short cycle nature of the smartphone business, more than half will disappear. While it is hard to pin down how much of this shortfall at the foundry level is due to component shortages and how much is due to competition for fab production time, the result is the same.

To add a bit of color, there are many fabless companies that have been double ordering in an attempt to meet customer demand, which has caused both foundry prices to rise and further tightening of foundry resources, especially at the 28nm level. This is particularly prevalent with generic parts, as opposed to the more customized ICs that are used in OLED display drivers, and Magnachip was quick to point out that their OLED driver customers, who are primarily South Korean panel producers, have not been doing so with them, giving them an accurate picture of hard demand. If this is the case, it makes what would be a ~15% OLED display driver ‘shortfall’ in 1Q a real measure of what the impact of IC foundry shortages can be. On the positive side, the company also indicated that it expects the foundry limitations will begin to ease toward the end of 1Q.

One unrelated point that also came to light during the Magnachip call had to do with foundry blackouts, a topic that seems to be quite visible recently. While Magnachip is fabless for their OLED driver products, they do have two internal fabs in Korea that are used for the production of power semiconductors. Last August, a crane operated by a city contractor damaged power lines, causing a blackout at one of the MX fabs that lasted for 6 minutes. While outages such as this tend to be focused on the cost in equipment damage, the real cost is time, given that much of the silicon in process when the outage occurs has to be scrapped and each process tool has to be restarted and run without commercial production until they meet pre-blackout specs.

There is much speculation about how long such a process can take, with company’s stating anything from ‘days to months’, but Magnachip was quite open about their the fact that the fab that experienced the 6 minute blackout ‘was not completely healed until October’, what we believe was a realistic assessment of recovery time. Based on that comment and using the middle of October as a target date, the fab took ~70 days to regain commercial production status. Every fab would be different, however this does put some parameters around such issues and we thank Magnachip for their transparency.

RSS Feed

RSS Feed