AU Optronics/Innolux Merger Rumors Squelched

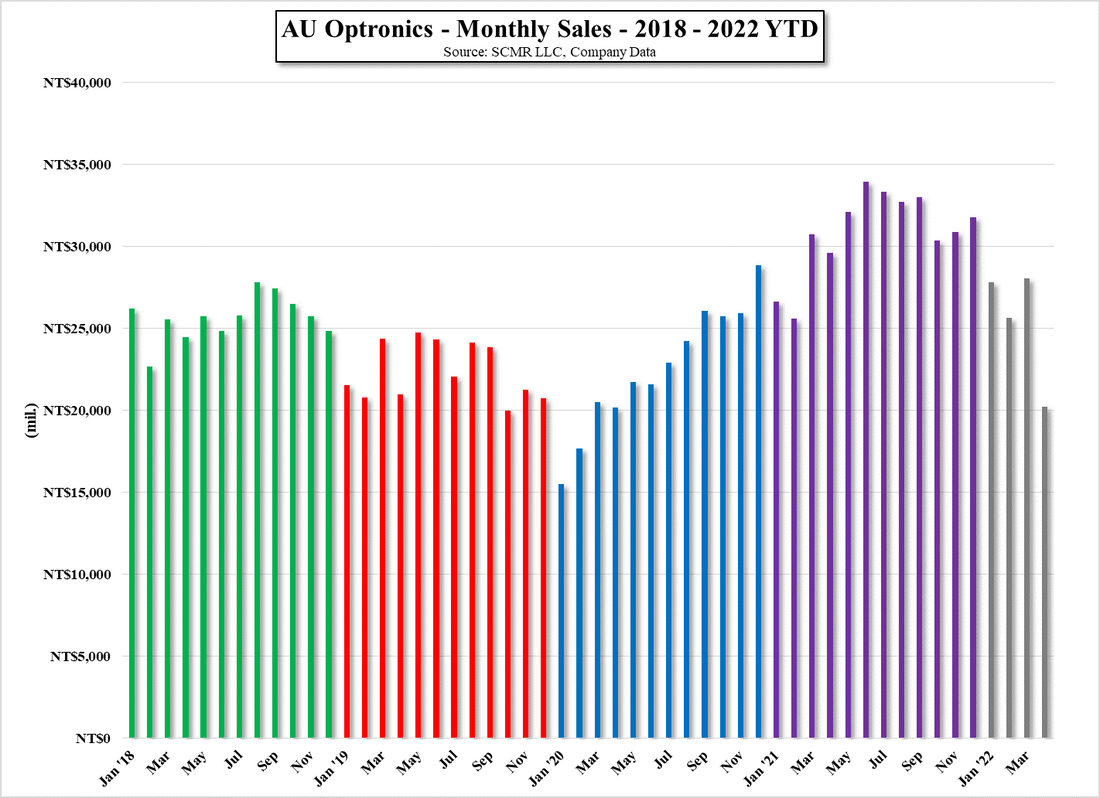

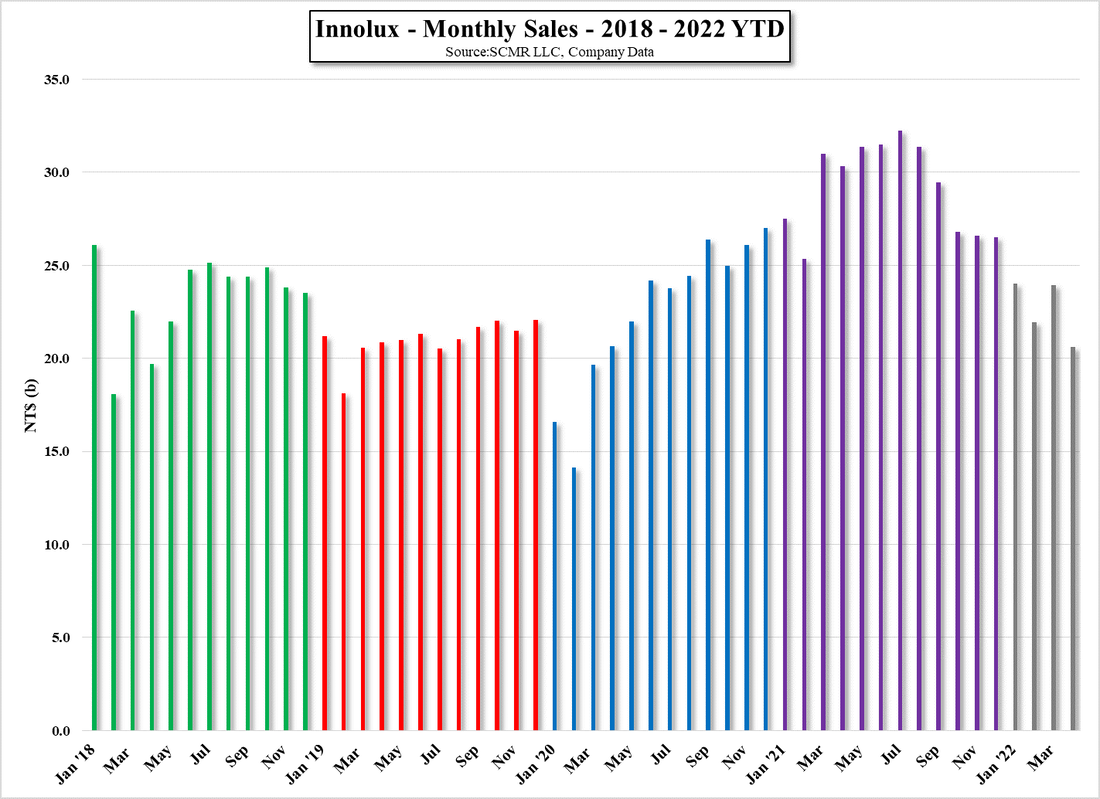

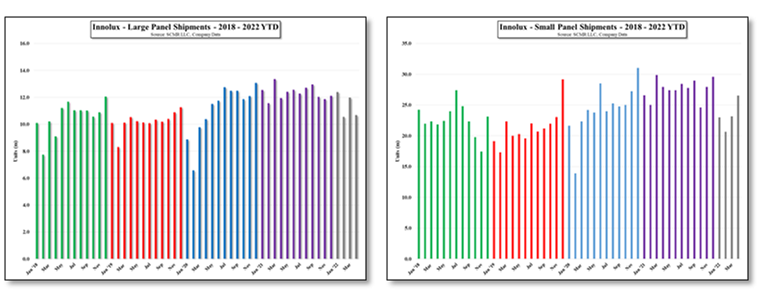

The problem with such a merger is the capacity that both parties already have and how that plays into today’s market. Both AUO and Innolux have significant Gen 5 and Gen 6 capacity, which is ideal for IT panel production, but combined lave less Gen 8 capacity than China’s leading TV panel producer BOE, which is essential for efficient TV panel production. Both also have a number of Gen 4 and Gen 5 fabs, which are relatively old and therefore inefficient by current standards. We note that AUO has recently indicated that it is planning to build a new Gen 8.5 LCD fab and has expanded capacity at its fab in Kunshan, the first capacity expansion project that the company has made in many years, and Innolux has stated it will not build any new LCD capacity but will upgrade existing LCD lines. With the continuing downturn in LCD panel pricing, we expect such plans are less prone to be rushed and the result of combining existing assets would likely also be less crucial.

RSS Feed

RSS Feed