One Small Step for Micro-kind

Size is an issue for any tool that must move such small devices from one location to another without damage however we also noted that Mini-LED backlights generate light to allow an LCD display stack to generate images while Micro-LEDs are self-emitting, meaning they produce the colored light that would make up an RGB display without a liquid crystal layer and a color filter. This is a huge difference that puts Micro-LEDs in a class far above LCD technology, however as self-emitters, three LED die (RGB) are needed for each pixel, which means that instead of what might be 10,000 or 20,000 singe color LEDs in a Mini-LED backlight, a 4K Micro-LED display would contain 24,883,200 individual LEDs, increasing the number of potential die transfers by over 1,000 times.

The die transfer time (moving die from wafer to substrate, even using the faster Luminex™ tool, would increase from 20 seconds (20,000 Mini-LEDs) to 6.9 hours for a 4K micro-LED display, making it infinitely more costly. But it doesn’t end there, as not only are there more LED die to transfer but as noted above they are much smaller, making the accuracy of placement on the substrate a much bigger challenge for Micro-LEDs than for Mini-LEDs, yet that is not the biggest problem that Micro-LEDs face. In order to create a Micro-LED pixel, one red, one green, and one blue Micro-LED would be needed.

Conveniently, blue and green LEDs can be grown on a substrate made of GaN (Gallium Nitride) by creating structures of InGaN (Indium Gallium Nitride) between substrate layers, however red LEDs are produced by using AlGaN (Aluminum Gallium Nitride) between the GaN layers. This means that red LEDs must be produced on a separate wafer while, in theory, blue and green LEDs can be produced on the same wafer. If all three structures could be produced on a single wafer, the complexity of transferring such vast numbers of small die could be greatly improved, but as it stands that has not been possible or practical. Not only do red LEDs cause this problem for Micro-LED developers, but unlike blue and green LEDs that maintain performance and their size decreases, red LED performance degrades rapidly as they are made smaller. This makes bringing down the size of an RGB pixel to what is necessary for Micro-LED applications problematic, as the performance of the red sub-pixel would be far less than that of the blue and green.

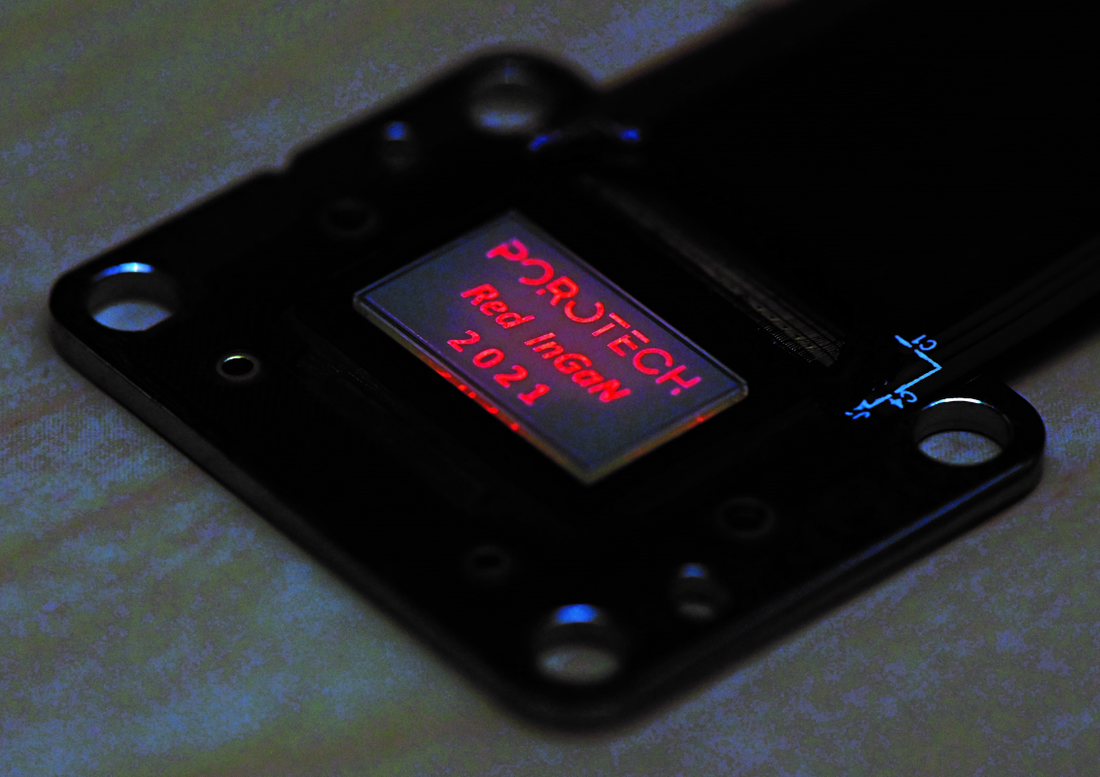

But all is not lost as a small start-up, actually a spin-off from the University of Cambridge, Porotech (pvt), says they have a solution that would allow red LEDs to be created on a GaN substrate using the same InGaN material structures as the blue and green LEDs, meaning all three could theoretically be produced on a single wafer, simplifying the transfer process and improving the characteristics of the red LEDs at the same time. This is done by changing the structure of the GaN substrate, creating a porous layer in the substrate that greatly improves the material’s optical characteristics while keeping its electrical characteristics unchanged. The company, which has only been in existence since last year, has raised ~$10m through a number of UK and Austrian VCs and has signed an agreement to work with Chinese micro-display producers Jade Bird (pvt), who will be using the Porotech substrate material to produce Micro-LED AR/VR displays.

While the technology is still a bit in the early stages, if it holds true that all three Micro-LED structures could be produced on the same wafer with similar characteristics, it would go a long way toward improving the prospects for the commercialization of Micro-LEDs and would eliminate all of the ways in which Micro-LED display designers now currently try to compensate for the technology’s shortcomings. There will still be many issues that engineers will have to face before Micro-LEDs become a competitive technology but when we see something that seems to be a big step toward putting a new technology on the path to commercialization, we like to make note.

RSS Feed

RSS Feed