Xiaomi OLED TV

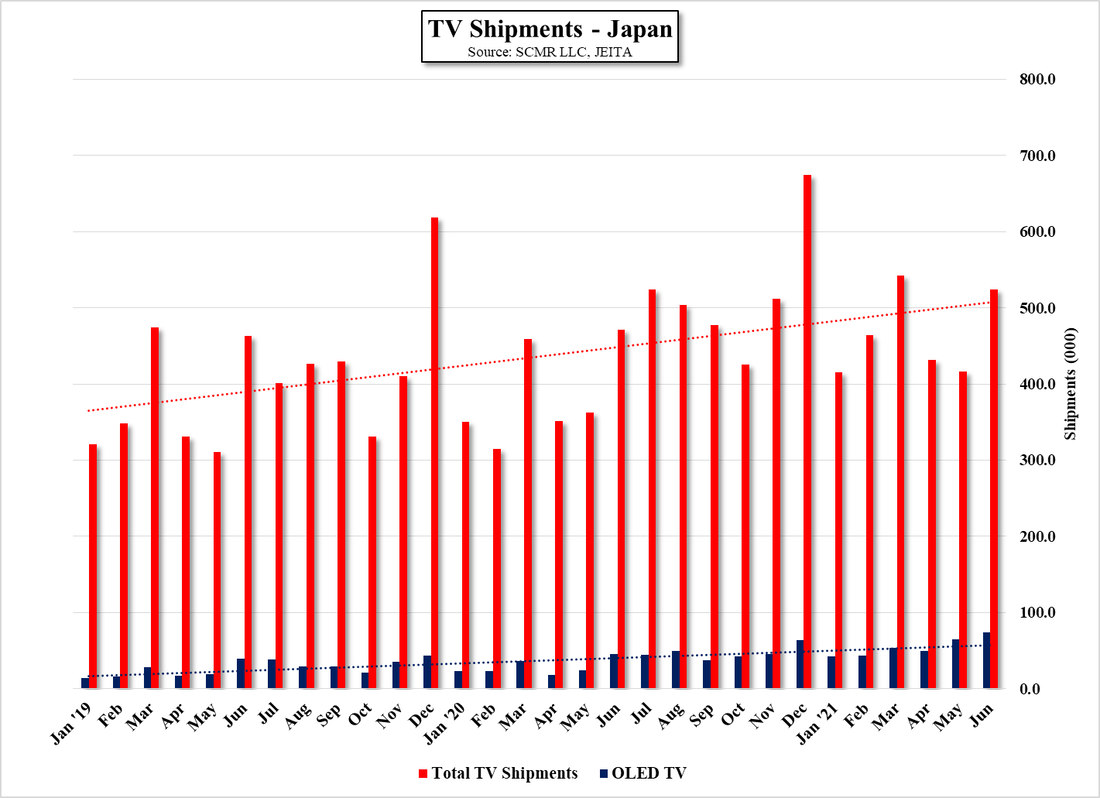

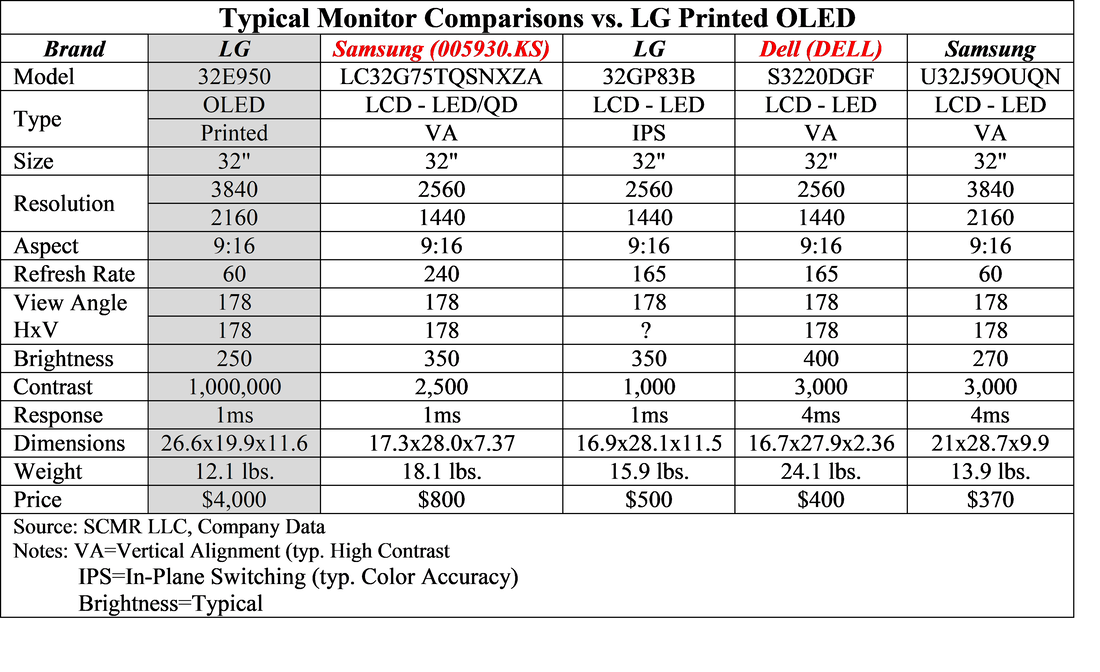

The sets are still expensive in Xiaomi terms, but are considerably lower priced than those produced by LG Display, Sony (SNE) and others. Without going into a detailed comparison of the features, mostly because all of the data is not yet available, the company’s 55” OLED model will sell for $771 (US) which compares to ~$1,300 for a Sony or LG model, most of which are last year’s models. The 65” Xiaomi OLED set will sell for ~$1,80 as compared to ~$1,800 similar sets from LG, and the Xiaomi 77” model will sell for ~$2,625 against prices between $2,800 and $3,300 for similar sets from others.

Again we note that these are price comparisons and don’t relate to feature sets and model characteristics, but we note that the only supplier of OLED TV displays is LG Display, so the panel price for Xiaomi and competitors would be the same or more depending on the quantity. If somehow Xiaomi is getting OLED TV panels from a Chinese supplier (not likely), the cost would likely be much higher given that LG Display’s yield, after years of production, would likely be far higher than a new producer.

Will Xiaomi’s entry into the OLED market begin to make the technology more popular in China? Perhaps, but Chinese consumers have been lukewarm toward the technology to date, likely because of a lack of local brands, but Xiaomi could help to give OLED TV a bit more momentum on the Mainland with such aggressive pricing. That said, the company has yet to revel whether these TVs will be released outside of China, and if so, at what price, so we expect relatively little impact on OLED TV brand share over the next year, but Chinese brands have a particular focus on share and a company like Xiaomi can withstand some losses in the OLED TV segment against it profitable mobile business and that could sustain such prices for some time. If Xiaomi OLED TVs stay local, the impact would be light, but that’s just what was thought of their smartphones years ago….

RSS Feed

RSS Feed